Product detail

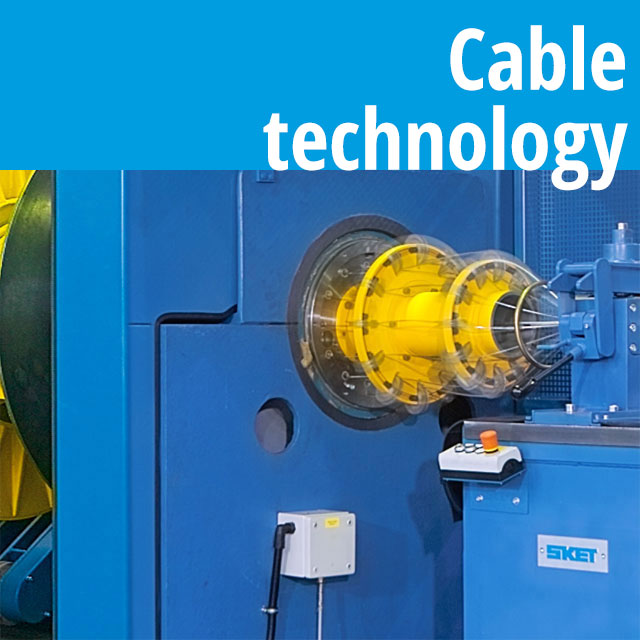

Sket VMB

The services and products provides by the stranding machinery company SKET Verseilmaschinenbau GmbH have enabled it to establish itself as a competent partner for the cable and wire rope industry in over 35 countries on all five continents. At its site, which covers a total area of 40,000 square metres and is home to production and assembly facilities covering an area of more than 10,000 square metres, the company designs and manufactures traditional, new and further developed machine systems for cable and wire rope production.

The innovations that make up SKET’s new equipment for the production of steel wire strands and steel wire ropes are dominated by special high-speed tubular stranders and planetary stranding machines from the company’s SRW und MKVS lines. These machines are designed to carry out processees such as manufacturing long and heavy wire ropes for offshore deep-sea applications. SKET has also developed special planetary stranding machines with back-twist and vertical stranding machines for the production of extremely long AC and DC offshore power cables with diameters of up to 350 millimetres. In order to achieve and ensure an excellent strand quality, SKET offers solutions such as the double-twist bunching machines in its MSDC and MSDN lines. The MKZT/S 700 central strander, which has revolutionised the use of stranding machinery in the field of cable production, enables previously unknown increases in both productivity and quality in conductor production.

SKET’s quality management guarantees the highest product quality and maximum supply reliability and its competitive edge in terms of technology.

The importance of the company is defined by its combination of traditions stretching back decades and technological innovations, key factors by which SKET Verseilmaschinenbau GmbH’s achievements are measured today and will be measured in the future.

PRODUCTS AND SERVICES

Cable Technology

Machinery for the production of power cables and special cables

- Central strander

- Planetary strander with back-twist

- Planetary strander without back-twist

- High-speed tubular strander

- Drum twister

- Single-twist strander

- Paper insulating and armouring machines

- Rewinding machines

Machinery for the production of OPGW cables

- Planetary strander with back-twist

- Planetary strander without back-twist

- High-speed tubular strander

Machinery for the production of off-shore power cables and umbilicals

- Planetary strander with back-twist

- Drum twister

- Laying-up machine

Steel wire rope technology

Machinery for manufacture of steel wire strands

- High-speed tubular strander

- Double-twist buncher (OUT-IN)

- Double-twist strander (IN-OUT)

- Planetary strander with back-twist

Machinery for manufacture of steel ropes

- High-speed tubular strander

- Planetary strander with back-twist

- Double-twist buncher (OUT-IN)

Machinery for manufacture of steel cord

- Double-twist buncher (OUT-IN)

Machinery for manufacture of PC-products

- Lines for making PC strands

Special machinery for manufacture of off-shore ropes

- Planetary strander with back-twist in singel and tandem configuration

including- rotating pay-off up to load of 200 t

- heavy traversing pay-offs and take-ups up to load 600 t

- double haul-off capstans with capstan diameter up to 5,000 mm

More information at: https://sketvmb.de/