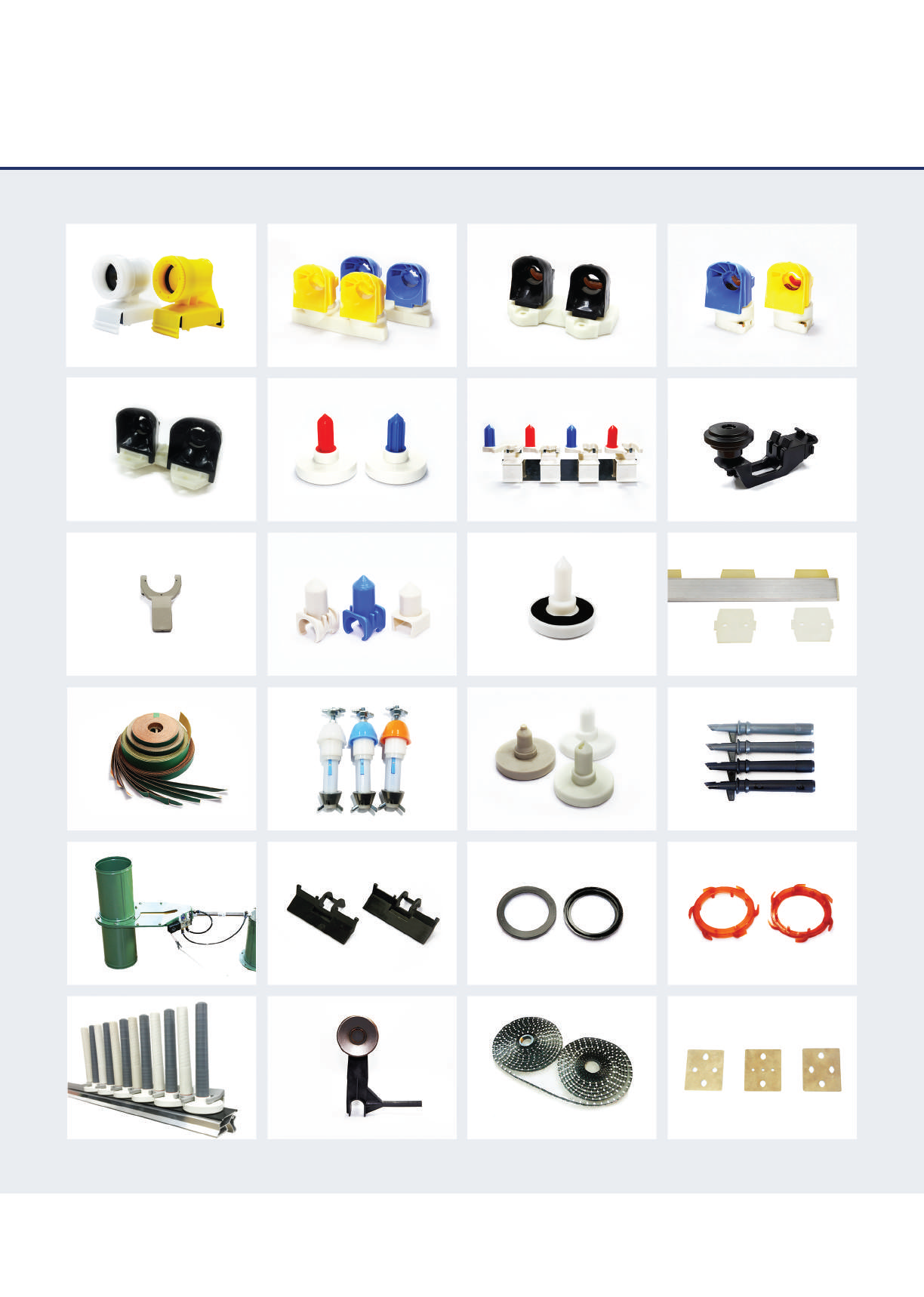

Product detail

Spinning, Open-end, Airjet,...equipment & parts

SPINNING

Established in 1984, YUIL MS Corporation has specialized in designing and manufacturing plastic injection molding products for spinning machinery.

We provide our customers with various core and spare parts optimized in auto-doffing system. Our major clients include Rieter Corp., Toyota Corp., and we work closely with each customer in insure effective communication and complete satisfaction.

With our effort in producing high quality spares, components and accessories for Textiles spinning machinery for more than 30 years.

We have established our own technology system and skills to provide best service for customers.

We will keep on leading the way and keep our highest standard. To be a good partner!

Download YUIL Catalogue here

OE (OPEN-END)

Baoding Jinqiao Spinning Machinery Parts Manufacturing Co., Ltd. (JSM), as a senior professional manufacturer of rotor spinning parts, has been committed to producing high speed rotor spinning parts. Our pursuit is to enable customers to produce more perfect yarns at a more reasonable cost. JSM promises to provide multi-specification and high wear-resistant coating rotor spinning parts.

Download JSM Catalogue here

BOBBIN HOLDER

Autotex has been serving to the textile industry for more than two decades and has grown to be one of the leading textile machinery component suppliers in India and Overseas. The company was set up with the express intention of manufacturing quality Plastic engineering parts to serve the Automobile, Engineering and Textile industry. An endeavor paved the way for manufacturing of Bobbin Holders and other textile machinery accessories.

Our quest for quality starts from design and ends at customer point through stringent in-house quality measures. This has made us one of the leading OEM supplier to quality conscious textile machinery manufacturers the world over. We strive for harmonical relationship with our customers by way of prompt delivery and excellent quality.

Download Autotex Catalogue here

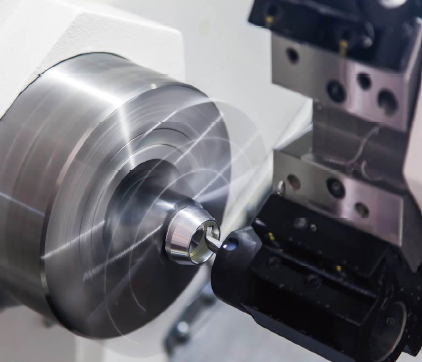

BEARING

MRS Bearingsestablished in 1992 by a team of experience technocrats from the bearing industry background to cater to the need of new generation technology for upcoming Industrial Era. The Company initially started with 5000 Sq Ft of Production Area and have expanded its production foot print to more than 80000 Sq Ft. The Company’s current manufacturing infrastructure consists of renowned production machinery & inspection equipment s from global sources from Sweden, Germany, Italy, US, China & India.

The complete sync & synergies between Man & Machinery allows high flexibility to produce consistent quality & variety products of products to the ever-changing customer requirements.

Download MRS Bearing Catalogue here